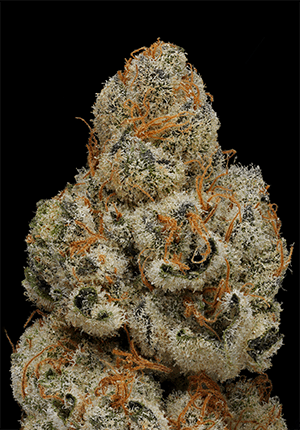

In the solventless extraction process, even more so than in hydrocarbon extraction, the quality of the input material is paramount. Because the live rosin end product contains the very essence of the plant that went into the press, it’s vital for operators to seek out the very best genetic lines and cultivars and the most freshly dried and cured plant material.

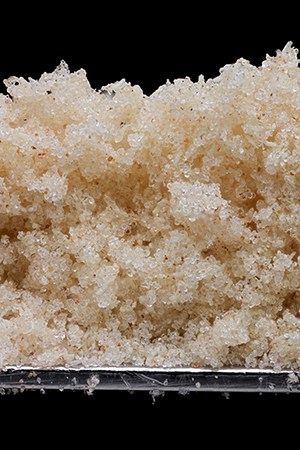

More specifically, the key is in the trichomes.

Solventless operators will typically find that trichomes in the 90- to 120-micron range make up the cream of their crops. The size will make it easier to capture the resin within during the pressing process. (This is why, on a related note, hemp varieties and cannabis trim tend not to work well with ice water hash washing, but do better with dry sifting.)

Cultivars (and genetics families) that tend to do well in the solventless process include: Chem strains, Papaya strains, Cake strains, Cookies and Cream, GMO, Banana OG, Do-Si-Dos, MAC, Tropicana Cookies, and many others with new winners seemingly being found daily. The bottom line: These cultivars are heavy resin-producers, often in the traditional “indica” or “hybrid” categories.

“When it’s pressed well, you tend to get the most original expression that the plant has to offer because it hasn’t been modified by all kinds of super high pressures and solvents taking things apart and putting it back together,” Vlosky says.

This is why top-notch plants are critical.

Starting out, though, this too becomes a bit of a balancing act. Operators won’t want to invest heavily in high-quality material before they’ve gotten a grip on the rosin press itself.

“Before you buy 20 pounds of something that you’re planning to wash and press, talk to the growers,” Vlosky recommends, adding that a half-pound or less of good fresh-frozen plant material might make for a helpful starting point for those looking to test. Talk through the genetics and the particular characteristics of a plant before going all-in on the rosin press.

On the back end of the process, when tracking KPIs and yield, operators will want to bear in mind that fresh-frozen buds have about a 75% moisture content. After washing and drying, the numbers look smaller than they are, so paying attention to that math is important. A good benchmark for live ice water hash yields is 3% or greater of the starting fresh-frozen weight, which in all dried material terms, is 4x, meaning 12%. Most producers seek strains that can do at least 4% from fresh frozen to dry hash, and some top strains have been known to yield as much as 8% or more (32% in terms of dry weight calculations).

But it’s more than simple numbers, too.

The solventless process also comes down to what’s long been known in the business as bag appeal. Does it look good? Does it smell good? These remain fundamental indicators, something qualitative to set next to the quantitative yield measurements.

After all, that’s how the consumer will be scrutinizing this product category on shelves or online.

“The consistent thing between all the producers who are attracted to solventless is that they all want to make a really high-quality product,” Vlosky says. “And even through newer markets, these [entrepreneurs] do their homework when they’re trying to start business. They don’t just think, ‘I’m just going to go do this. I hope it works out.’ These businesses and these owners want to make a company that’s going to be successful, obviously. But the people that are really focused on quality, they pick it up quick and they’re trying to get ahead of the curve.”

One way that businesses have gotten ahead of the curve is by working with passionate hash makers, many of which were chefs or cultivators previously. In a way, the rosin press mechanism treats plants similarly to how chefs might treat the ingredients that go into a well curated meal. Whereas the farm-to-table dining concept has picked up a lot of consumer interest in recent years, the farm-to-nail concept might shine through in the solventless extraction process.

Understanding heat is critical to the successful live rosin producer.

Vlosky offers that 160-200 degrees Fahrenheit is a good range to keep in mind for most live rosin products. He adds that older material or lower-quality material might demand more heat, while better-quality-material might need less heat. “It’s all about experimentation,” he says.

And while there’s certainly a roadmap to excellent live rosin products in place, thanks in large part to the team at PurePressure, the game is still one of individual creativity and entrepreneurial spirit.

What sort of solventless products do you want to create?

“A lot of the elite geneticists, a lot of the elite breeders, when they come up with a big solventless strain that they’re really proud of it’s a big deal,” Vlosky says. “And a lot of the solventless breeders are trying to make strains that are popular for solventless because it’s extra brownie points. Not only is your strain good, but it washes well and presses well. And then all the connoisseurs, they kind of glom onto that. That’s a positive thing.

“As markets mature, that demand for solventless concentrates really grows once people find out, ‘OK, first of all, I like concentrates and infused products and, OK, this is my farm-to-table analogy here.’”

It’s an easily explained narrative that tracks with other consumer interest trends, and it’s a major reason why solventless live rosins are becoming a more visible part of the cannabis market.