A hands-on cannabis college focused on industry education, training, career placement, medical cannabis and more has expanded to central Florida.

Learn Sativa University’s (SATU) hands-on program has been in operation for roughly four years. The university started in a 1,000-square-foot building, but has recently expanded to a 5-acre cannabis farm and training facility in Apopka, Fla., said Patrick O’Brien, SATU founder and CEO.

The primary purpose of the college is pretty “straightforward,” O’Brien said.

“We aim towards two paths, and we’re looking for two types of individuals: either ones looking to land rewarding careers in the industry, or individuals looking to start businesses. Whether it be in cultivation, dispensary, or anything along those lines, we can assist with business plans, curriculum and everything from top to bottom,” he said.

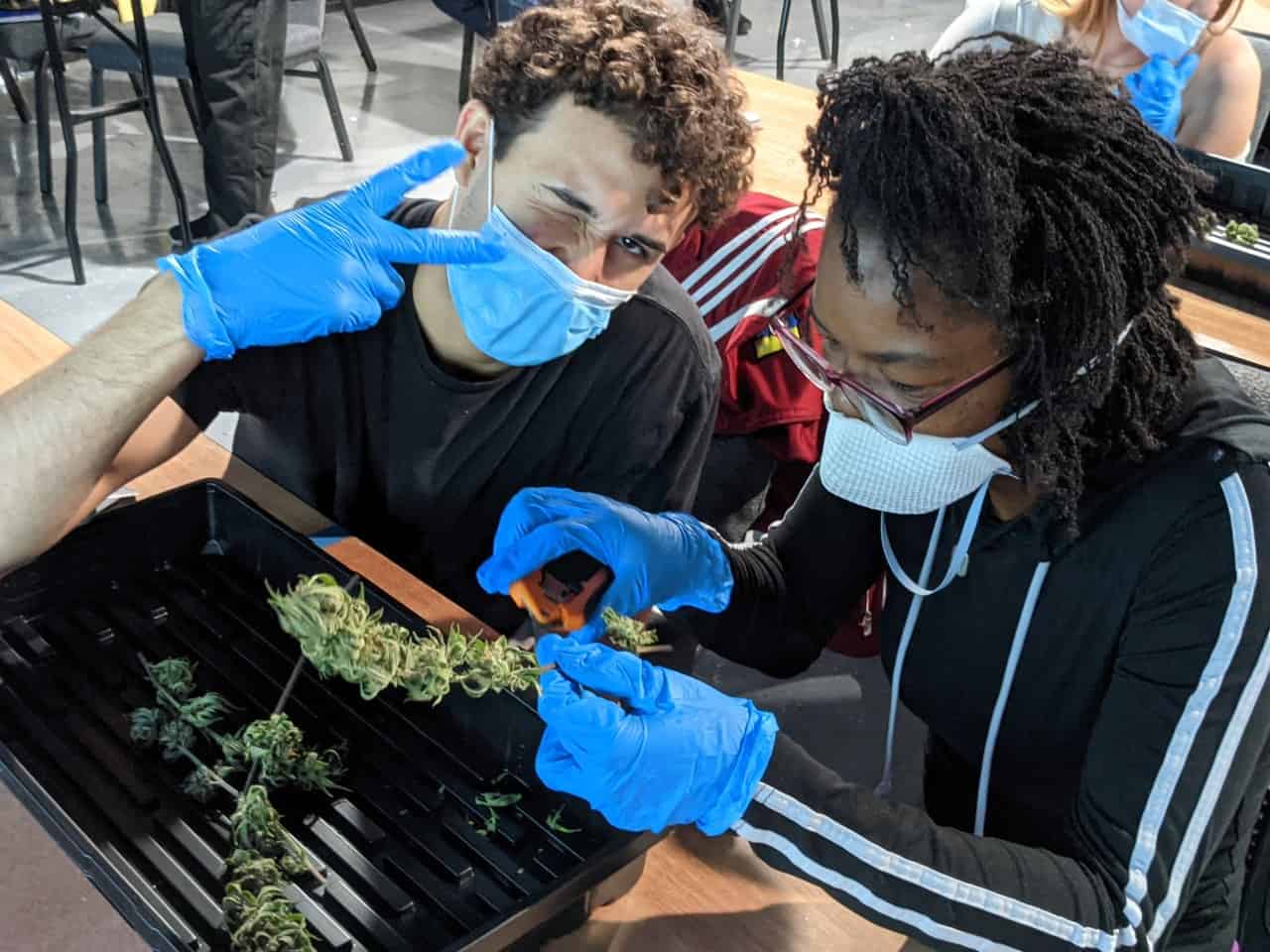

He said that the campus features an indoor climate-controlled grow and a 50,000-square-feet outdoor greenhouse where students can learn through hands-on training. The college also offers online training for those who cannot attend in person.

SATU’s hands-on and online courses include Marijuana Cookbook, Marijuana Laws, Marijuana Careers, Marijuana History, Marijuana Growing and Dispensary Management.

Each course is a one-time 8-hour class, and students receive a certificate tailored to the subject upon completion, he said.

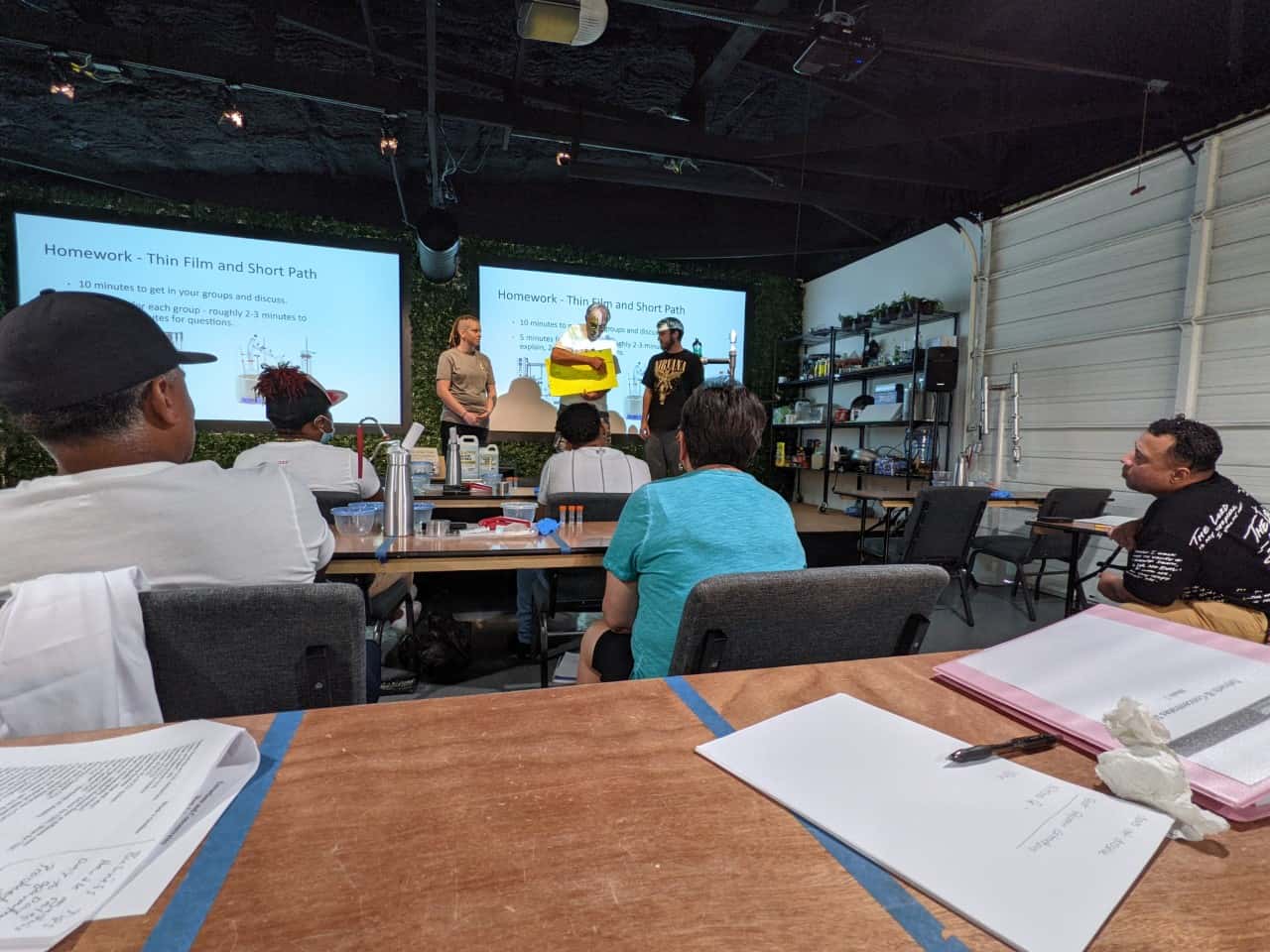

© Courtesy of Learn Sativa University

Students at SATU

“Everybody starts with dispensary management. That is our core curriculum,” O’Brien said. “The reason we start there is you have to have a wide understanding of all your opportunities in the industry. I have people who come and say, ‘I want to be a cultivator,’ and then they find out about extractions and completely shift their mindset. So, once you take that, we do provide you with advanced courses and consultation programs that you could get into advanced cultivation.”

After students receive a certificate in dispensary management, they can enroll in the other courses based on the career path they are interested in or the business they are looking to launch, he said.

“[For example] a very popular thing I hear lately is a lot of people want to get into food trucks, and extraction is a very important process for that,” he said. “So, typically they’ll take an extraction [course] and go through a business course, as we cover all the laws, legalities and everything from top to bottom. We offer that so that they can get their license legally and they could start that project without having to worry about their doors getting kicked in.”

© Courtesy of Learn Sativa University

The university also provides in-person students with lunch, books, study materials, lab equipment and much more.

“We provide everything from top to bottom to ensure that they’re prepared,” O’Brien said. “Typically, what ends up happening is a lot of people will come out here. They’ll take a vacation with their family. They’ll go ahead and complete the course, and then they can fly home. And then some of them tend to want to stay for the advanced courses, or others will come back a month or two later for those.”

“A lot of people want to test the waters at first because it’s still very crazy to hear the idea that there’s an actual cannabis college where you can come and acquire this knowledge,” he added.

SATU has had over 50,000 students enroll in either an online or hands-on course to date, and O’Brien said he’s had students from places like Brazil, Puerto Rico, Colombia and India.

While the courses prepare students for entry-level positions in the industry, O’Brien said several local companies and larger corporations have reached out to the SATU seeking qualified individuals to fulfill open positions.

“We have billion-dollar companies right now coming to us, like Curaleaf,” he said. “[These] companies are coming to us asking us for staff that are qualified, trained and have expertise in what we’re preparing them for, and it’s very exciting because now we have students in all these different management positions that only request Learn Sativa students within those facilities. That’s not all companies, but the ones especially local to us.”

“And beyond that, we’re starting to see a lot of the companies out in the [recreational] states currently requesting this,” he added. “The states themselves are requesting that you have a school backing to get the license, and they’re using our school to do that. It’s an amazing thing.”

© Courtesy of Learn Sativa University

Additionally, SATU features a dispensary that sells in-house products made by students.

“Some of the students that really take to creating incredible products, we will partner up, work with them and do a share so that they actually get a cut of products they sell through that program,” he said. “So, it’s a way for us to allow students to test out some of their products, and those change once in a while, but it just depends on who comes through the door.”

For example, an SATU student from Colombia who has a background in chemistry created a CBG oil, O’Brien shared, and the college worked alongside him to help launch that product.

“Essentially, what we’re providing to our students is a set of instructions,” he said. “They follow them; they end up with an end result. Sometimes it’s incredible. Sometimes it’s mediocre. It just depends how much they put into it.”

“The beauty I think behind this program is the networking,” he said. “If all you’re lacking is a little bump of tools, that little toolset you need, or the skills, maybe you need to just develop them; that’s what we provide you. So, long as you’re willing to swing that hammer, the sky’s the limit.”